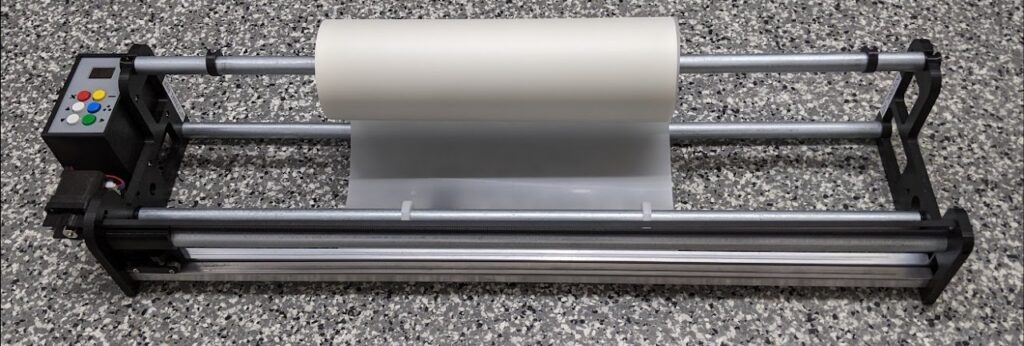

FILM ROLL TO SHEET CUTTING MACHINE

Krexil’s film roll to sheet cutting machine brings precision, speed, and versatility to your film processing workflow. Whether you’re cutting DTF, sublimation, window tint films, or other thin films, this solution turns bulky rolls into clean, pre-sized sheets. It’s designed for businesses that value consistency, reduce material waste, and want a more efficient way to manage film rolls. Ideal for small setups and industrial production alike.

WHY CHOOSE OUR FILM CUTTING MACHINE?

Benefits of Using a CNC Film Cutting Machine

Our film cutting machine uses CNC automation to deliver smooth, accurate cuts across a wide range of film types. This precision helps eliminate manual errors and supports consistent sheet sizes for various applications. The digital control system makes it easy to set dimensions and replicate jobs with minimal setup time. It’s perfect for both one-off and recurring production runs.

Precision, Efficiency and Low Waste Output

Krexil’s solution is built for clean performance and productivity. Adjustable settings support different film widths and lengths, ensuring perfect cuts every time. This efficiency reduces material loss, improving your bottom line. Whether you work with short batches or large volumes, our cutter keeps operations running smoothly.

VERSATILE FILM CUTTING APPLICATIONS

DFT Film Cutting for Print-on-Demand

Krexil’s DTF film cutting machine is ideal for creating pre-sized PET sheets used in garment decoration. These sheets are easier to handle, store, and align for heat transfers. Print shops benefit from simplified workflow and improved print registration. It’s a must-have for fast-paced, custom printing environments.

Sublimation Film Cutting for Hard and Soft Surfaces

Our sublimation film cutting machine supports cutting sublimation rolls into manageable sheets for use with flatbed or desktop printers. This prevents feeding issues and ensures smooth handling. Whether you print on garments or rigid surfaces, this setup enhances accuracy and reduces labor. It’s ideal for on-demand production teams.

Sheeting Solutions for Medical and Laboratory Films

Medical-grade films such as polyurethane and PET are frequently used as covers, barriers, or device components. Our machine allows cleanroom-ready sheeting for simplified handling and storage. Labs benefit from better control during packaging and testing procedures. The result is a safer, more efficient environment.

Film Sheeting for Packaging and Sample Packs

Manufacturers of sachets, blister packs, and trial kits often need small-format film sheets. Our film roll cutting machine transforms BOPP, PE, and foil rolls into accurate, production-ready sheets. This flexibility supports rapid prototyping and cost-effective short runs. It’s perfect for marketing packs and limited-edition products.

Window Film Cutting for Tint and Solar Applications

The Krexil window film cutting machine enables precision sheeting of solar and tint films for installations or retail kits. This saves time during installation and cuts down on film waste. Retailers and tinting pros get neat, demo-friendly pieces with minimal effort.

Reflective Film for Safety and Signage

Reflective films are critical in signage, road decals, and safety labels. Our cutter ensures accurate sizing for short and urgent jobs. Pre-cut sheets allow faster production for temporary or specialty signage. Perfect for municipalities, construction firms, and safety gear makers.

ENHANCE WORKFLOW WITH FILM ROLL DISPENSER & CUTTER

Handling Flexibility with Film Roll Cutting Machines

An integrated film roll dispenser keeps rolls aligned and ready for cutting, reducing tangling and feeding errors. You can switch between narrow and wide rolls quickly without retooling. This makes it easy to handle different film types within the same session. Your team spends less time adjusting and more time producing.

Boosting Productivity in Small and LArge Operations

Our film roll cutting machine adapts easily to various production sizes and setups. Whether you run a one-person shop or a multi-line factory, the system boosts throughput with minimal learning curve. High-speed cutting translates into faster deliveries and greater customer satisfaction. It’s built for reliability and scale.

TALK TO US ABOUT YOUR FILM TYPE

Have a specific film in mind or unsure if it’s compatible? We’re happy to help. From specialty packaging films to medical-grade substrates, we’ll test samples and tailor the cutter to your needs. Whether you need a standard film cutting machine or something customized, our experts are here to advise. Reach out with your specs—we’ll handle the rest.

FINAL THOUGHTS

Krexil’s film roll to sheet cutting machine gives you full control over how you convert and manage thin films. With CNC precision, broad material support, and a built-in film roll dispenser, it’s built for performance and reliability. Whether you cut DTF, tint, or sublimation films, our system helps streamline your process, save time, and reduce waste.

FREQUENTLY ASKED QUESTION

1. What kinds of film can your cutter handle?

Our machine works with DTF, sublimation, PET, BOPP, foil, PE, polyurethane, reflective films and most thin films.

2. Can it handle short and custom runs?

Yes, it’s designed for both small batches and large-scale production, making it ideal for on-demand jobs.

3. Is this a good solution for tint film sheeting?

Absolutely. Our tint film cutting machine creates ready-to-install sheets with high precision.

4. How can I check if my film is compatible?

Just contact us with your film specs or send a sample—we’ll verify compatibility and provide a tailored recommendation.